Orange Juice Production Line

Retail Price:

CNY: 10000000

/set

Min. order:

1 Piece

Stock:

99 Piece

Delivery Time:

day

For the latest best price,please chat with us.

- Product Introduction

- Specifications Packaging

- After Sales Guarantee

-

- Commodity name: Orange Juice Production Line

- Company: /set More parameters>>

Orange Juice Production Line

Orange juice is a popular beverage enjoyed by people all over the world. The process of producing orange juice involves a series of steps that ensure the quality and safety of the final product. In this article, we will take a closer look at the orange juice production line, from the selection of oranges to the packaging of the juice.

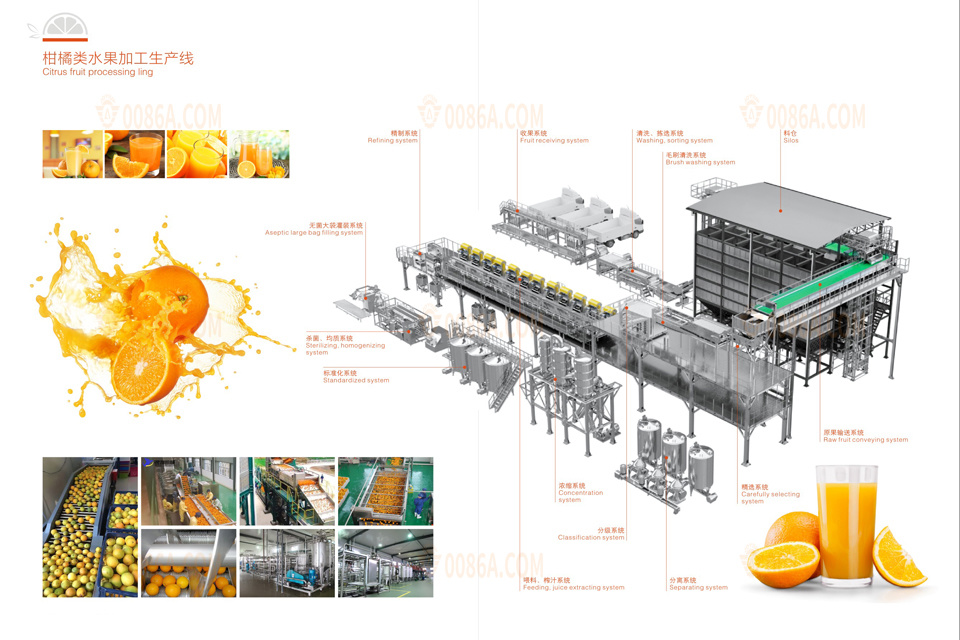

1. Selection of Oranges

The first step in the orange juice production line is the selection of high-quality oranges. Oranges are typically sourced from citrus groves that meet strict quality standards. These oranges are carefully inspected to ensure that they are ripe, fresh, and free from any defects. Only the best oranges are selected for juicing, as the quality of the oranges directly impacts the taste and nutritional value of the final product.

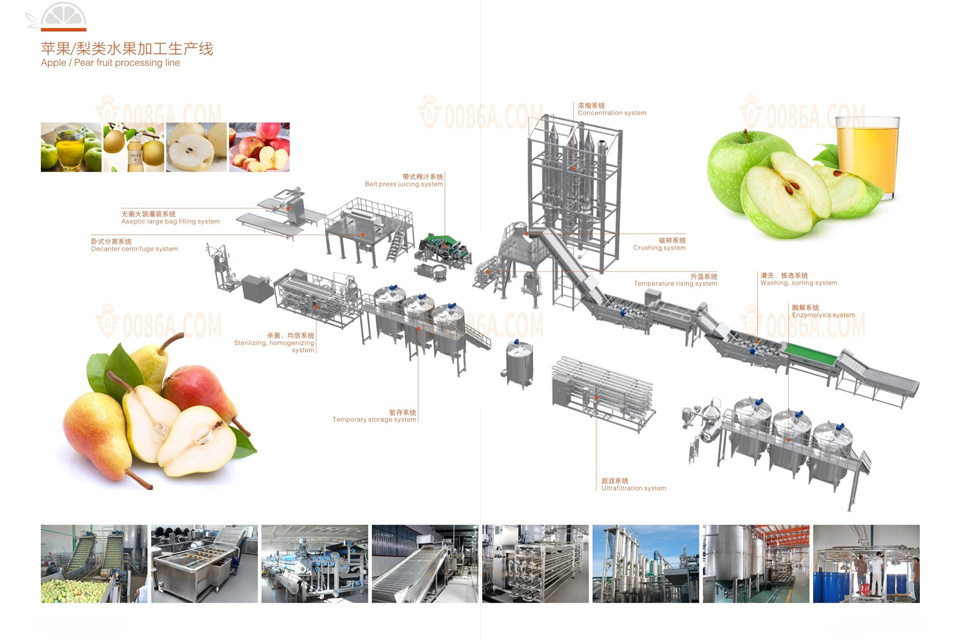

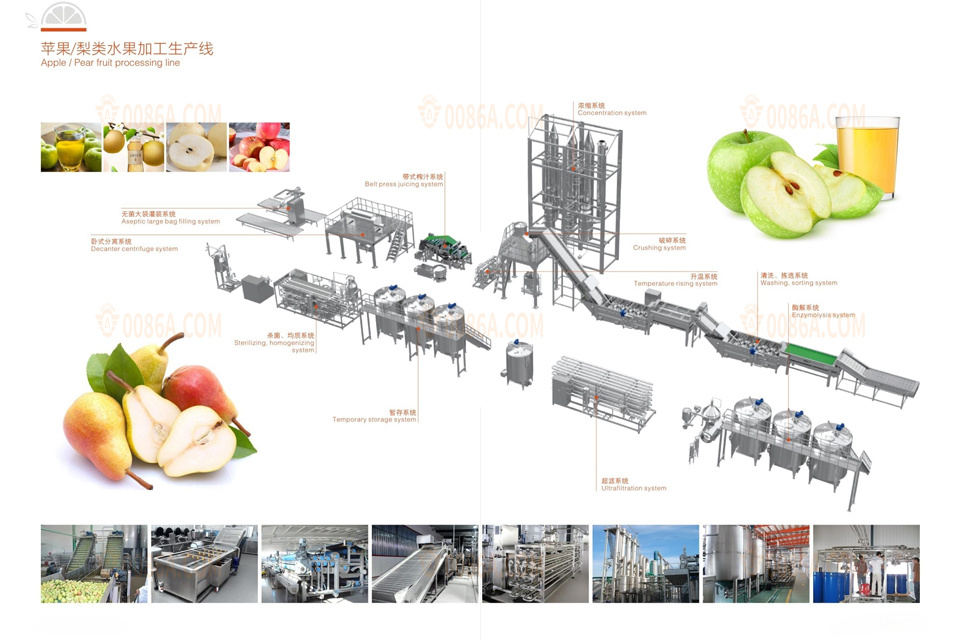

2. Washing and Sorting

Once the oranges have been selected, they are washed to remove any dirt, debris, or pesticides that may be present on the skin. After washing, the oranges are sorted based on size and ripeness. This ensures that the oranges are uniform in size and flavor, resulting in a consistent and high-quality juice.

3. Juicing

After washing and sorting, the oranges are ready to be juiced. The oranges are fed into a juicing machine, where they are squeezed to extract the juice. The juice is then filtered to remove any pulp or seeds, leaving behind a smooth and delicious liquid. Some manufacturers may also pasteurize the juice to extend its shelf life and ensure its safety.

4. Blending and Flavoring

Once the juice has been extracted, it may be blended with other juices or flavors to create different varieties of orange juice. For example, some manufacturers may add apple or pineapple juice to create a unique flavor profile. Additionally, sugar or sweeteners may be added to enhance the taste of the juice. These ingredients are carefully measured and mixed to ensure a consistent and delicious product.

5. Packaging

After the juice has been juiced, blended, and flavored, it is ready to be packaged. Orange juice is typically packaged in cartons, bottles, or cans, depending on the manufacturer's preference. The packaging is designed to protect the juice from contamination and light exposure, ensuring that it remains fresh and flavorful. Once the juice has been packaged, it is labeled with nutritional information, expiration dates, and other important details before being shipped to retailers.

In conclusion, the orange juice production line is a complex process that involves several steps to ensure the quality and safety of the final product. From the selection of oranges to the packaging of the juice, each step is carefully managed to produce a delicious and nutritious beverage that can be enjoyed by consumers around the world. By understanding the production process, consumers can make informed decisions about the orange juice they purchase and consume.

Send Query

Please leave us a message and we will reply within 24 hours